How Digital Printing is Transforming the Fashion Industry

How Digital Printing is Transforming the Fashion Industry

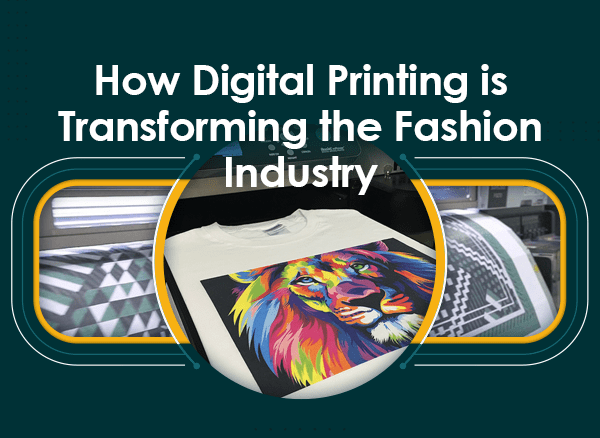

The textile industry is currently experiencing a revolution in the way that textiles are consumed due to the continually shifting preferences of people throughout the world. Since its founding, the industry has seen significant material and technological advancements. One of the most exciting advancements in the textile sector is digital fabric printing. It has raised the bar and satiated growing textile printing demands. The technology of digital printing makes it possible to print anything on cloth flawlessly and quickly.

High-resolution pattern and image prints have grown in popularity within the clothing industry as a result of the introduction of inkjet technologies for fashion and apparel applications over the years, from intricate floral and animal prints to finely detailed photorealistic images and monotonous, complicated brand designs.

The largest barrier to more widespread technological adaptation has been the price of digital printing. Users love the technology’s adaptability and the creative possibilities it provides, but manufacturers of the machines and inks are collaborating closely with the industry to make it more conducive to mass production.

As the leading sustainable clothing manufacturer in India, We have extensive textile and garment printing capabilities and experience to meet even the most stringent international standards.

Some possible advantages are highlighted by fashion companies considering digital fabric printing:

By switching to digital printing, designers are no longer constrained by physical dying and screening. With digital printing, you can access an infinite variety of colours and designs that are produced with excellent visual clarity.

Moreover, digital printing is a considerably more environmentally friendly choice than analogue, or conventional, printing because it consumes less energy, creates less waste, and has a lower overall carbon footprint.

Digital printing creates patterns that look amazing. Depending on the specific needs of the client, it can match a wide range of visible color spectrums.Because the method gives designers the freedom to rapidly modify patterns and colors and print a sample before engraving screens for the final run, mass customization is possible.On the same fabric, digital inkjet printing allows for almost immediate manufacture.

Digital printers may still create the greatest print characteristics even though they don’t need a lot of set-up or cleanup time in between patterns. Another benefit is the elimination of screen costs for sample and small manufacturing runs.

These technologies are making the manufacturing process more efficient, opening up new design options, and improving the purchasing experience for consumers. We may expect even more intriguing advancements in the future as the sector adapts to new changes.

Recent Posts

-

Understanding Sustainable Fabric Options Available in India

Understanding Sustainable Fabric Options Available in IndiaIn today's generation of heightened environmental consciousness and sustain...

Read more -

The Comfort and Sustainability of Organic Cotton Sweatshirts

The Comfort and Sustainability of Organic Cotton SweatshirtsConcerning cozy and environmentally friendly apparel, eco-conscious consume...

Read more -

How to Outsource Clothing Manufacturing: Exploring Pros and Cons for Small Fashion Businesses

How to Outsource Clothing Manufacturing: Exploring Pros and Cons for Small Fashion BusinessesWhen considering outsourcing clothing manufacturing, it's crucial to conduc...

Read more -

T-Shirt Fabric Guide: What Is the Best T-Shirt Material to Wear?

T-Shirt Fabric Guide: What Is the Best T-Shirt Material to Wear?Choosing the right T-shirt fabric is crucial for comfort, style, and durabi...

Read more -

What Is Slow Fashion & Why It's Important

What Is Slow Fashion & Why It's ImportantSlow fashion is a movement and approach to clothing and fashion that priori...

Read more