Leverage the immense “commercial possibilities” of a diverse array of designs, looks, and textures in the fabrics you use or in your finished products. As an integrated clothing manufacturing house, we have the capabilities to print as well as treat/precure fabrics and garments according to your specifications using a wide range of colorants and technologies.

Print your fabrics and garments to give them the look and feel you wish.

We have extensive textile and garment printing capabilities and experience to meet even the most stringent international standards.

All Over Prints (AOP) mean prints all over the fabric. Placement prints on the other hand as the name suggests is the printing of artwork on specific areas of the garment, for example, the back pocket of a pair of trousers, the front of a T-shirt, and so on. Unlike AOP which is usually done at the fabric stage, this is done when the garment is ready.aaa

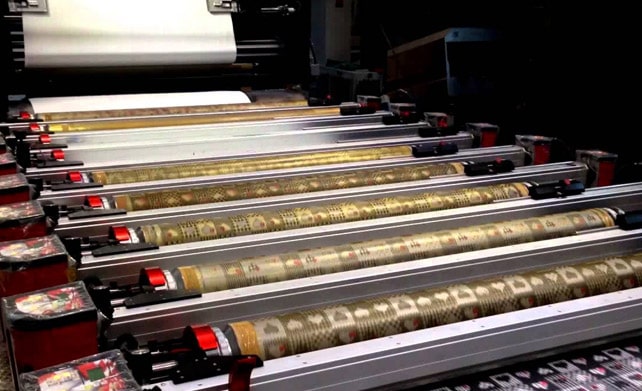

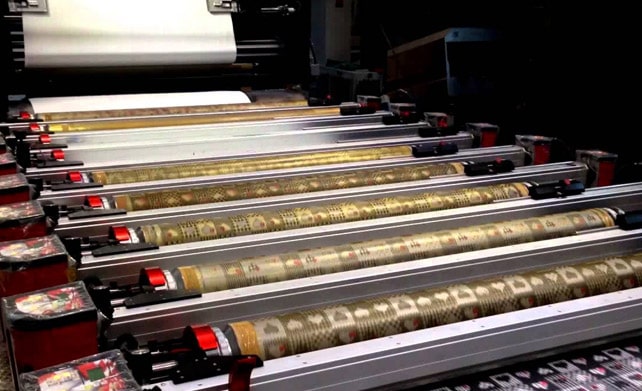

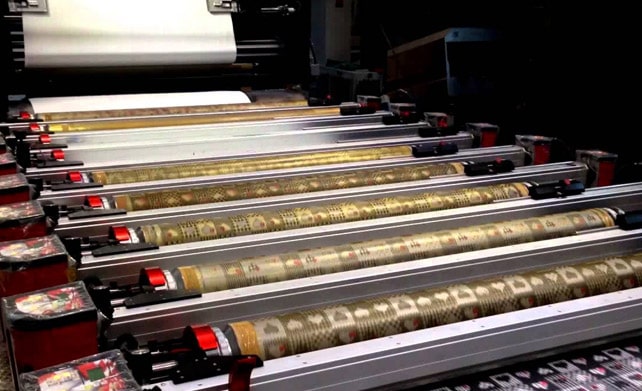

We can produce high quality printed textile using the Rotary Screen Printing technology on a commercial scale.

Get continuous all over prints (AOP) of complex patterns all over the fabric with this technology. We can print designs up to12 colors.

We are capable of different types of Rotary prints using various ink like Water-based Pigment, non-PVC inks or PVC based ink.

This type of printing is suitable for both natural and synthetic fibers.

Sublimation printing is a permanent printing process meant for polyester or polyester blends, synthetic material usually of a light color. We can do this for AOP as well as for placement prints.

The prints are bright, of high resolution, smooth while being washable. So, there is no fear of the prints getting scraped or scratched.

We can print patterns with water-based non-PVC inks without toxic phthalates and other harmful chemicals. They may be pigment/dye-based. This is an eco-friendly printing process.

We can use water-based inks for discharge printing to create patterns on fabrics, and garments made from organic fibers or tri-blends.

These prints add a stylish vintage look to the fabric.

This printing method can be used for both Rotary Screen AOP or Placement prints for T-shirts and other garments.

Embellish your products with foil, embossing, specialty coating, glitter, sparkles and more…

We provide various treatments to the fabrics to impart different functionalities as required by our clients. Here’s a basic run through the different treatments and washes we provide and the effects they have on the fabrics.

Enzyme wash makes the fabric look and feel soft without affecting the strength of the fabric in any way.

This treatment imparts a weathered and faded look to the fabric that is quite a rage now. It can be done on most of the fabrics be it naturals, synthetics, or blends cost-effectively.

This involves abrading the fabric with stones/acid/cellulase enzymes to give it a stylish worn and weathered look while giving it a soft feel at the same time.

This treatment softens the fabric while imparting a silky smoothness to the surface of the fabric. It also increases its tear resistance and the luster of its colors.

Treating garments with permanganate neutralizer removes the residue stains left in garments during bleaching and makes them bright.

Bio-washes improve the shine and the softness of garments.

This treatment can control the growth of bacteria, mold, and bad odor in clothes in hot and humid conditions for many hours. A property loved by all garment wearers!