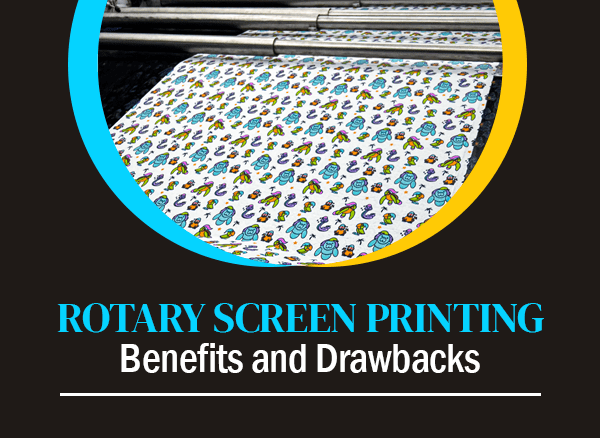

Rotary Screen Printing: Benefits and Drawbacks

Rotary Screen Printing: Benefits and Drawbacks

Our nation presently uses rotary screen printing extensively for printing. This technique is widely used in everyday life, including clothing, accessories, and even home décor.

Although rotary screen printing has many advantages, it also has certain drawbacks. It will continue to be the clear decision in the long run for several production types. However, rotary screen printing is under more competition as new design capabilities from other printing techniques appear.

Benefits:

– The manufacturing pace of rotary screen printing is unmatched, reaching up to 120 yards per minute.

– Large-scale cloth printing is especially well suited for rotary printing. It is the best option for high-volume garment production because it is a productive method that may reduce costs and save time.

– It is possible to produce different versions of the same design using rotary printing by changing the cylinder’s base. As a result, the printing process is more flexible and customizable. Additionally, the use of up to eight colors in a single print gives clothing manufacturers more creative options.

– As many as 12 different colors can be applied to each screen, which is separately operated.

– Compared to other printing techniques, particularly digital printing, rotary printing is significantly more affordable.

Drawbacks

– Each color has its own screen, so if you’re producing a color-heavy print, the expense might quickly add up. Furthermore, all of those costs are incurred during the sampling procedure; picture the monetary consequences if the consumer does not like the sample.

– This printing technology does not allow for intricate print clarity and precision. Because this procedure cannot create photos, it is now regarded a significant limitation. It is harder to attain clarity when printing smaller details on clothes, as opposed to digital printing. While the overall quality is excellent, it is tough to attain if the design incorporates multiple minute details.

– The registration of the fabric may be affected by high-speed printing since the cloth can readily distort.

– The main drawback of rotary screen printing is the high equipment fixed cost. Due to the clean-up and machine downtime when changing patterns, the machines are typically not viable for short yards of drastically varied patterns.

Although rotary screen printing is the tried-and-true fabric print technique, it has a cost that can only be fulfilled if running a substantial volume of production. Rotating screen printing has unsurpassed production speeds and abilities, yet pricing is an impediment to entryway.

Aryan Apparels provides Rotary Printing Services in India. We can produce numerous rotary prints utilizing different inks, such as water-based pigment, non-PVC inks, or PVC-based ink, which can work with both natural and artificial fibers.

Connect with us to know more.

Recent Posts

-

Understanding Sustainable Fabric Options Available in India

Understanding Sustainable Fabric Options Available in IndiaIn today's generation of heightened environmental consciousness and sustain...

Read more -

The Comfort and Sustainability of Organic Cotton Sweatshirts

The Comfort and Sustainability of Organic Cotton SweatshirtsConcerning cozy and environmentally friendly apparel, eco-conscious consume...

Read more -

How to Outsource Clothing Manufacturing: Exploring Pros and Cons for Small Fashion Businesses

How to Outsource Clothing Manufacturing: Exploring Pros and Cons for Small Fashion BusinessesWhen considering outsourcing clothing manufacturing, it's crucial to conduc...

Read more -

T-Shirt Fabric Guide: What Is the Best T-Shirt Material to Wear?

T-Shirt Fabric Guide: What Is the Best T-Shirt Material to Wear?Choosing the right T-shirt fabric is crucial for comfort, style, and durabi...

Read more -

What Is Slow Fashion & Why It's Important

What Is Slow Fashion & Why It's ImportantSlow fashion is a movement and approach to clothing and fashion that priori...

Read more