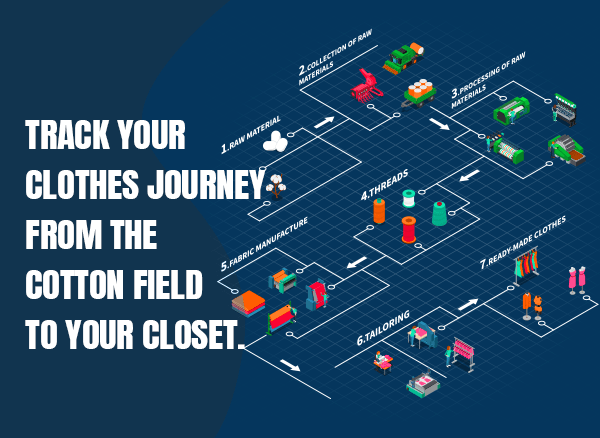

Track Your Clothes Journey from the Cotton Field to Your Closet

Track Your Clothes Journey from the Cotton Field to Your Closet

Have you ever wondered about the journey of your clothes before they reach your wardrobe? If your answer is “No,” then it’s high time to reconsider. Knowing the real journey of a fabric or a cloth is really exciting. As the Best Apparel Manufacturer in India we’re happy to share our experience, methods, process, with you all. We are a reputable and certified company specialized in custom apparel manufacturing and exporting. With extensive experience and a proven track record, we offer comprehensive services, including product designing, sourcing, manufacturing, and accessorizing. Our top priority is ensuring the highest quality in every aspect of our operations. Additionally, we also provide packaging and delivery services for a complete end-to-end solution.

Tracking the journey of your clothes from the cotton field to your closet involves understanding the supply chain and various processes involved in the production and distribution of clothing items. Here’s an overview of the typical steps involved:

Cotton Cultivation: This is the first step. The journey begins in cotton fields where farmers cultivate cotton plants. The plants are grown, and cotton bolls are harvested once they ripen.

Cotton Ginning: After the cotton bolls have been carefully harvested from the fields, the next crucial step in the cotton production journey takes place at cotton gins. These gins serve as vital hubs where the raw cotton undergoes essential processing to prepare it for its transformation into the versatile material we know and love.

Spinning: At spinning mills, the raw cotton fibers embark on the captivating transformation into yarns, an essential process that unlocks the true potential of cotton as a versatile textile material. Here, amidst the rhythmic hum of machinery and the skillful guidance of textile artisans, the cotton fibers undergo a mesmerizing metamorphosis.

Weaving/Knitting: The yarn is now woven or knitted into fabric at specialized facilities. Weaving involves interlacing vertical (warp) and horizontal (weft) yarns to create woven fabric. Knitting, on the other hand, involves creating loops of yarn to form a flexible fabric structure.

Dyeing/Printing: Once the fabric is produced, it may be dyed or printed with various colors and patterns. This adds aesthetic value to the fabric and creates different designs for the final clothing item.

Garment Manufacturing: The dyed or printed fabric is then sent to garment manufacturing units. Here, our skilled workers cut and sew the fabric into the desired clothing items, following patterns and designs.

Quality Control: Before leaving the manufacturing unit, the garments undergo quality control checks to ensure they meet the required standards for durability, sizing, and overall quality.

Distribution and Transportation: After passing quality control, the finished clothing items are packed and transported to distribution centers, warehouses, and retail stores. In some cases, they may also be sold online through e-commerce platforms.

After the above steps, the clothing items are displayed in retail stores, where customers can purchase them. Alternatively, customers can buy them online, and the items are shipped directly to their doorsteps. Finally, after purchase, the clothing item finds its way to your closet, where you can wear and enjoy it. This is a story of your clothes journey from cotton field to your wardrobe.

How clothes get made from the exciting inspirations/ideas you have is a very interesting process. It’s methodical and extremely specific. Remember perfection lies in little things done well, nonetheless, it’s super exciting to say the least.

Check our process to know in detail:

Design Submission: When you bring your design ideas and tech pack/s to us, we begin by collaborating to finalize the production details. If you’re a new brand without any tech pack, there’s no need to worry. We offer assistance in building your tech pack/s and provide support for other relevant design submissions to ensure a smooth and successful production process. Our goal is to help turn your concepts into reality and create exceptional products tailored to your vision.

Sourcing/Product Development: We source all types of necessary material as per your requirement and develop your products paying attention to the minutest of specs like selection of fabrics, trims, mock ups, visual examples of seams, even labels and packaging.

Sample Development: Once the product design is finalized and agreed upon, we proceed to the pre-production sampling stage. This crucial phase involves several steps to ensure the highest level of quality and accuracy.

Bulk Production: Once we receive your approval for the pre-production samples or sew samples, we move forward to initiate bulk production, and your designs start to come to life! As the production process advances, we create the TOP (Top of Production) sample. This sample is taken from the actual bulk production and serves as a final confirmation of the product’s quality, appearance, and adherence to the approved design.

Quality Control Inspection: Quality control is at the core of our strengths, and we take immense pride in our rigorous quality checks and high production standards. Our dedicated and experienced quality team is uncompromising in their pursuit of excellence throughout the production process. We are committed to delivering products with utmost precision, adhering to your specified tolerance levels.

Delivery: We understand the importance of a seamless delivery process, and that’s why we pack your products precisely as per your preferences before shipping them. Your dream creations are carefully packaged and sent right to your doorstep, ensuring a hassle-free experience for you.

Selecting the right apparel manufacturing company is a critical decision that can significantly impact the success of your fashion business. Whether you are a budding designer, a fashion startup, or an established brand, partnering with the best manufacturing company can make a world of difference in ensuring product quality, meeting deadlines, and achieving long-term growth. We’re the Top Textile Exporters in India to help you with your journey.

Connect With Us to know more about our services.

Recent Posts

-

Understanding Sustainable Fabric Options Available in India

Understanding Sustainable Fabric Options Available in IndiaIn today's generation of heightened environmental consciousness and sustain...

Read more -

The Comfort and Sustainability of Organic Cotton Sweatshirts

The Comfort and Sustainability of Organic Cotton SweatshirtsConcerning cozy and environmentally friendly apparel, eco-conscious consume...

Read more -

How to Outsource Clothing Manufacturing: Exploring Pros and Cons for Small Fashion Businesses

How to Outsource Clothing Manufacturing: Exploring Pros and Cons for Small Fashion BusinessesWhen considering outsourcing clothing manufacturing, it's crucial to conduc...

Read more -

T-Shirt Fabric Guide: What Is the Best T-Shirt Material to Wear?

T-Shirt Fabric Guide: What Is the Best T-Shirt Material to Wear?Choosing the right T-shirt fabric is crucial for comfort, style, and durabi...

Read more -

What Is Slow Fashion & Why It's Important

What Is Slow Fashion & Why It's ImportantSlow fashion is a movement and approach to clothing and fashion that priori...

Read more